Rocket® TRUcentrix™ can assist in the monitoring, collection and approval of time sensitive product quality documentation. Manually tracking documents via email and spreadsheets through the various the PPAP steps is time-consuming, error prone and inefficient. With TRUcentrix, just as with APQP, you can deploy a PPAP tracking application whereby a supplier can provide status updates for all assigned PPAP tasks and upload associated deliverables for OEM review and approval.

What is the Production Part Approval Process (PPAP)?

Production Part Approval Process (PPAP) is used in the automotive supply chain as part of the APQP standard to verify a manufacturer’s ability to produce and consistently provide an automotive part that fully complies with purchase requirements.

The PPAP process is designed to demonstrate that the component Supplier has developed their design and production process to meet the client’s requirements, minimizing the risk of failure by effective use of APQP. PPAP’s are verified by the submission of a series of documents making up the PPAP package.

The result of this process is a series of documents gathered in the PPAP Manual /Package which requires a formal approval by the Supplier and Customer. The form that summarizes this package is called Part Submission Warrant (PSW) and confirms that sample parts have been supplied to and meet a given level of documentation and process/product development. In Germany, this may be an ISIR (initial sample inspection report); the approval of the PSW indicates that the Supplier’s responsible individual (usually the Quality Engineer) has reviewed this package and that the Customer has not identified any issues that would prevent its approval.

The PPAP manual requires detailed documentation on each of the items listed in the PPAP Elements Table

PPAP Elements Table

| Order | PPAP Element |

|---|---|

| 1 | Design Records |

| 2 | Engineering Change (note) Documents |

| 3 | Engineering Approval |

| 4 | DFMEA |

| 5 | Process Flow Diagram |

| 6 | PFMEA |

| 7 | Control Plan |

| 8 | DFMEA |

| 9 | Dimensional Results |

| 10 | Material and Performance Tests |

| 11 | Initial Process Studies |

| 12 | Qualified Laboratory Documentation |

| 13 | Appearance Approval Report |

| 14 | Sample Production Parts |

| 15 | Master Sample |

| 16 | Checking Aids |

| 17 | Customer-Specific Requirements |

| 18 | Part Submission Warrant (PSW) |

The content of the Manual / Package is determined by the PPAP submission Level.

Level 1- PSW ONLY

Level 2- PSW with product samples and limited supporting data

Level 3- PSW with product samples and complete supporting data

Level 4- PSW and other requirements as defined by the customer

Level 5- PSW with product samples and complete supporting data available for review at the manufacturing location

Critical Elements of the Process Approach

- Process owner exists

- Process is defined

- Process is documented

- Linkages of process established

- Process monitored, analyzed and improved

- Records maintained

PPAP/APQP approval

Suppliers are required to obtain PPAP approval from the vehicle manufacturers whenever a new or modified component is introduced to production, or the manufacturing process is changed. Obtaining approval requires the Supplier to provide sample parts and documentary evidence showing that:

- The client’s requirements have been understood.

- The product supplied meets those requirements.

- The process (including sub suppliers) is capable of producing conforming product.

- The production control plan and quality management system will prevent non-conforming product reaching the client or compromising the safety and reliability of finished vehicles.

PPAP is the confirmation that the product meets the customer requirements for series production.

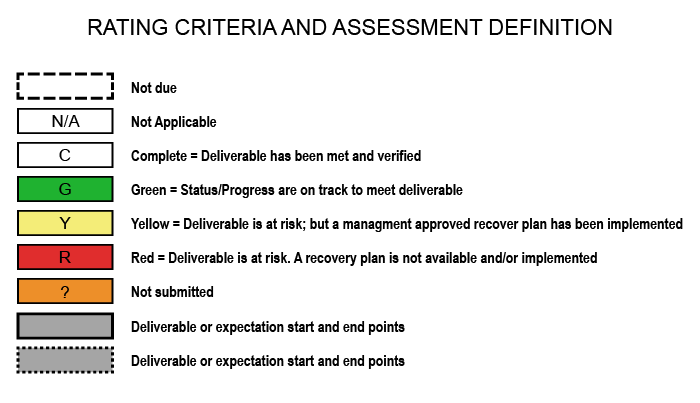

The status of these deliverables drives the rating (Red/Yellow/Green/Complete/NA) status for each element.